Our Services

Casting Sourcing & Machining

Depending on customer requirements and the level of complexity, we start by manufacturing the patterns and core boxes made from either wood or a lost foam. Castings can come in a variety of alloys and we are able to machine Ni-Hard, 28% Chrome, Stainless Steel, Duplex, Titanium, Bronze, Aluminum, Cast and Ductile Iron, and Carbon Steels.

Facing to tapping of internal threads or removing draft angles on tightly tolerance bores are some common secondary machining requirements. E.C.-Tech has extensive resources for complete machining and finishing to satisfy any customer requirements.

CNC & General Machining

Using current technology, CNC and conventional machinery we are able to assist our customers with a variety of services and handle everything from custom, small to large volume production runs without compromising the speed or final quality of the product.

With a fast paced and changing industry we are able to offer a wide variety of High Vacuum components, Jigs & Fixtures, Dies, Bend and Shear Tooling, Turnkey Solutions and repairs/maintenance…. From design through to precision manufacturing and assembly, we are capable of collaborating and sharing concepts and ideas with a wide range of customers.

Engineering

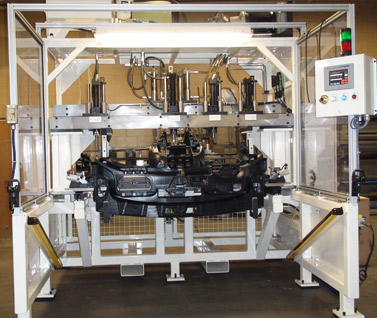

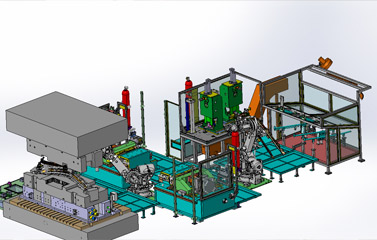

Our engineering department is capable of designing Special Purpose/Custom Machinery and Solutions and Automated Work Cells, Check Fixtures, Tooling, Dies, Jigs & Fixtures.

With key partners with over 40 years of experience in hydraulic and electrical components including valves, manifold, actual piston pump, motors, cylinders, and computer control of hydraulics. Our system integration group can provide any level of control integration desired by the customer. This can range from mechanical, pneumatic, electrical and hydraulic including complete PLC and PC based host and operating software.

Using the latest software such as Solidworks and Mastercam, CNC and Conventional Machinery we are able to assist our customers with a variety of services. We can assist customers in concept development, mechanical structural design, Pneumatics and Hydraulics, Robot Endeffectors (EOAT) Simulation and Automation.

Capabilities

One of E.C.-Tech’s strongest assets is our team of talented and experienced Machinists, Designers and key partners allowing us to provide a full range of Mechanical, Hydraulic, Pneumatic and Electrical Design, 3D Designs including detailed drawing packages and reports per customer standards, and Customer Prototypes with trials and testing all done in house.

Industries We Serve

automotive

pulp & paper

oil & gas

hydro electric

Mining & Construction

turbo machinery

Contact us today to learn more about what we can do for your business.

London, Ontario

N6E 1P6